Turning Insert, Grooving Tool, Indexable End Mills, Multifunctional Milling Tools, End Mills

GLOBAL LEADER OF TUNGSTEN CARBIDE CUTTING TOOLS

FOR MACHINING DIFFICULT TO CUT MATERIALS

เครื่องมือตัดคุณภาพสูงระดับโลก สำหรับตัดงานแข็งมาก อาทิ Die & Mold, Turbochager, Aerospace parts, Automotive parts, Oil & Gas, Pump & Valves และงาน General machining

• เทคโนโลยีชั้นนำผลิตจากทังสเตนคาร์ไบด์ นวัตกรรม WC-Co ขนาด 0.2 μm รายแรกของโลก แข็งแรงกว่า ต้านทานการสึกหรอ Tool life ที่ยาวนานนิ่งขึ้น

• ตอบโจทย์การใช้งาน กลึง มิลลิ่ง งานเจาะ ฯลฯ หัวจับระบบ ผลิตชิ้นงานที่มีความยาก แม่นยำ

• นวัตกรรมใหม่ ในราคาดีกว่า ช่วยท่านประหยัดต้นทุน

ผลิตภัณฑ์ที่มีเทคโนโลยีคุณภาพสูง มีความแข็งแรง ทนทาน เหนียว และทนทานต่อการเสียดสี ทนต่อการสึกกร่อน

PRODUCT FEATURES

Insert ผลิตภัณฑ์ที่มีเทคโนโลยีที่แตกต่างซึ่งมีความแข็ง ความเหนียว และความทนทานต่อการเสียดสี

Negative Type

| Chip Breaker | Chip Breaker Design | Features | |

|---|---|---|---|

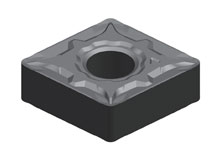

| F11 (Finishing) |

|

|

– Optimized in finishing machining ISO S, M materials – Prevents B.U.E with sharp edge – Enhanced chip evacuation – High rake angle applied in side cutting edge (→ Minimize cutting forces and heat resistance) |

| M11 (Medium) |

|

|

– Optimized in ISO S, M materials – Prevents B.U.E with sharp edge – Strong cutting edge-reduce boundary damage – Wide chip pocket (→ Stable chip evacuation) |

| R11 (Roughing) |

|

|

– Optimized in roughing machining ISO S, M materials – Excellent for cutting edge strength – Designed for deep depth of cut (→ Excellent for deep depth of cut at high feed) |

| M22 (Medium) |

|

|

– Optimized in medium machining ISO S, M materials – Prevents B.U.E with sharp edge – Sharp cutting edge & low cutting force – Stable chip pocket (→ Reduce force of chip evacuation ) |

| M51 (Medium / Finishing) |

|

|

– Universal chip breaker – Prevents B.U.E with sharp edge – Sharp cutting edge & low cutting force – Enhanced chip breaker (→ Excellent chip evacuation at Low feed, depth of cut) |

| M21 (Medium) |

|

|

– Optimized in medium machining ISO S, M materials – Prevents B.U.E with sharp edge – Sharp edge & low cutting force – Stable chip pocket (→ Reduce force of chip evacuation) |

| M51 (Medium / Finishing) |

|

|

– Optimized in roughing machining ISO S, M materials – Excellent cutting edge strength – Designed for deep depth of cut (→ Excellent for deep depth of cut at high feed) |

| M51 (Medium / Finishing) |

|

|

– Optimized in medium machining ISO S, M materials – Prevents B.U.E with sharp edge – Sharp edge & low cutting force – Waved cutting edge (→ Reduce cutting force) NANOLOY |

Positive Type

| Chip Breaker | Chip Breaker Design | Features | |

|---|---|---|---|

| F11 (Finishing) |

|

|

– Optimized in finishing machining ISO S, M materials – Prevents B.U.E with sharp edge – Enhanced chip evacuation (→ Stable chip evacuation in Finishing) |

| M11 (Medium) |

|

|

– Optimized in ISO S, M materials – Prevents B.U.E with sharp edge – Strong cutting edge – reduce boundary damage – Wide chip pocket (→ Stable chip evacuation) |

| R11 (Roughing) |

|

|

– Optimized in roughing machining ISO S, M materials – Excellent cutting edge strength – Designed for deep depth of cut (→ Great for deep depth of cut at high feed) |

| M51 (Medium / Finishing) G class |

|

|

– Universal chip Breaker – Prevents B.U.E with sharp edge – Sharp edge & low cutting force – Enhanced chip breaker (→ Excellent chip evacuation at Low feed/depth of cut) |

| 2FM (Medium / Finishing) G / M class |

|

|

– Optimized in ISO S, M materials Finishing and Medium – Prevents sharp edge adhesion – Enhanced chip evacuation – G class machining – G/M class (Selectable) |

Grooving Tool

Indexable End Mills

Solid Carbide End Mills

ผลิตภัณฑ์ที่มีเทคโนโลยีคุณภาพสูง มีความแข็งแรง ทนทาน เหนียว และทนทานต่อการเสียดสี ทนต่อการสึกกร่อน

NANOLOY End Mills for Stainless Steel

N-SM series

Excellent tool life for stainless steel machining with superior NANO ultrafine grade

End mills for stainless steel

1. Superior material, coating, geometry for stainless steel machining

2. Excellent performance in ISO M,S materials

3. Wide range of applications with various geometries and specifications

PRODUCT FEATURES

Unique powder, special geometry, coating guarantee excellent cutting performance in stainless steel & titanium machining

– Provide highest machining quality and tool life with excellent cutting edge in difficult to cut materials machining

– Longer tool life and minimization cutting force with high lake angle cutting edge and enhanced edge resistance

NANOLOY End Mills for hardened materials

N-SH series

Excellent tool life for hardened material machining with superior NANO ultrafine grade

End mills for hardened material

1. Specially designed for machining hardened material(HRC45 ~ 65)

2. Excellent quality and performance for automotive and mold industry

3. Apply optimal design for cutting edge and coating

→ improve wear resistance and toughness

PRODUCT FEATURES

Apply for optimized material and coating guarantee excellent cutting and tool life in automobile and mold industry hardened material machining.

- Improve productivity, reduce cutting force at high speed machining

- Improve surface quality, high precision machining with high quality of end mills

- Stable machining with optimized rake-angle and clearance angle

- Excellent tool life with excellent NANO ultra grade and coating

PRODUCT FEATURES (TOOL LIFE TEST)

TS1125 NANO Series Tool Life Test – Ball Nose End Mill

NANOLOY vs. Competitor – wear resistance

- Processing operations : Profiling milling

- Workpiece : SKD11(HRC60)

- Coolant : Wet

Precision Products

Precision Products สำหรับการปรับโฟกัสอัตโนมัติของกล้องสมาร์ทโฟน

แม่เหล็กพลาสติก

ผลิตภัณฑ์ที่ขับเคลื่อนด้วยมอเตอร์ความเที่ยงตรงประสิทธิภาพสูงพร้อมเทคโนโลยีเสียงรบกวนต่ำ

การบีบอัดแม่เหล็ก NdFeB ที่ถูกผูกมัด

ผลิตภัณฑ์ที่ขับเคลื่อนด้วยมอเตอร์ความเที่ยงตรงประสิทธิภาพสูงพร้อมเทคโนโลยีเสียงรบกวนต่ำ

ND Sintered Magnet (แม่เหล็กถาวร)

ผลิตภัณฑ์ที่ขับเคลื่อนด้วยมอเตอร์ไดรฟ์ที่แม่นยำพร้อมเทคโนโลยีที่มีลักษณะเฉพาะและทนความร้อนสูง

NANOLOY DRILL INSERT SERIES NEGATIVE INSERTS (VNMG) |

POSITIVE INSERTS (DCMT/DCGT) DCMT070202-F11 DCMT070204-F11 DCMT11T302-F11 DCMT11T304-F11 DCMT11T308-F11 DCMT070204-M11 DCMT070208-M11 DCMT11T304-M11 DCMT11T308-M11 DCMT11T312-M11 DCMT11T308-R11 DCMT11T312-R11 DCGT070202-M51 DCGT070204-M51 DCGT11T301-M51 DCGT11T302-M51 DCGT11T304-M51 DCGT11T308-M51 POSITIVE INSERTS (SCMT) SCMT09T304-F11 SCMT09T308-F11 SCMT09T304-M11 POSITIVE INSERTS (TCMT) TCMT06T102-F11 TCMT06T104-F11 TCMT06T108-F11 TCMT090202-F11 TCMT090204-F11 TCMT110204-F11 TCMT110302-F11 TCMT110304-F11 TCMT110308-F11 TCMT16T304-F11 TCMT090204-M11 TCMT090208-M11 TCMT110308-M11 TCMT16T304-M11 TCMT16T312-M11 TCMT16T308-M51 POSITIVE INSERTS (VBMT/VBGT) VBMT110302-F11 VBMT110304-F11 VBMT110308-F11 VBMT160404-F11 VBMT160408-F11 VBMT160404-M11 VBMT160408-M11 VBMT160412-M11 VBMT160412-R11 VBGT160404-F11 VBGT160404-2FM VBGT160408-2FM VBGT160412-2FM POSITIVE INSERTS (VCMT/VCGT) VCMT110304-F11 VCMT160404-F11 VCMT160408-F11 VCMT110304-M11 VCMT160404-M51 VCMT160408-M51 VCGT110302–M51 VCGT110304–M51 VCGT160402–M51 VCGT160404–M51 VCGT160408–M51 N-MT INSERT & HOLDERS 2NG30N-04M-F1 2NG40N-04M-F1 2NG40N-08M-F1 2NG50N-02M-F1 2NG50N-08M-F1 2NG30N-04M-M1 2NG40N-04M-M1 2NG40N-08M-F1M 2NG50N-08M-F1M 2NG30R-15M-M1 N-MT INSERT & |

HOLDERS 2NG20N-02G-F1 2NG20N-04G-F1 2NG27N-08G-F1 2NG30N-04G-F1 2NG30N-08G-F1 2NG40N-04G-F1 2NG40N-08G-F1 2NG50N-08G-F1 2NG60N-02G-F1 2NG60N-04G-F1 2NG60N-08G-F1 2NG80N-04G-F1 2NG80N-08G-F1 2NG80N-12G-F1 2NG50N-02G-F1M 2NG50N-04G-F1M 2NG50N-08G-F1M 2NG30R-15G-M1 2NG50R-25G-M1 2NG60R-30G-M1 2NG80R-40G-M1 N-MT INSERT & HOLDERS NG2EHR/L2020-T09 NG2EHR/L2020-T13 NG2EHR/L2525-T09 NG2EHR/L2525-T13 NG2EHR/L2525-T15 NG3EHR/L2020-T09 NG3EHR/L2020-T11 NG3EHR/L2525-T09 NG3EHR/L2525-T11 NG3EHR/L2525-T15 NG3EHR/L3225-T15 NG3EHR/L3225-T20 NG4EHR/L2020-T11 NG4EHR/L2525-T11 NG4EHR/L3225-T15 NG4EHR/L3225-T20 NG5EHR/L3225-T15 NG5EHR/L3225-T20 NG5EHR/L3232-T20 NG5EHR/L3225-T25 NG6EHR/L2525-T20 NG6EHR/L3225-T20 NG6EHR/L3232-T20 NG8EHR/L3232-T30 Ball nose insert endmill for general NBGT-GS-5R NBGT-GS-6R NBGT-GS-8R NBGT-GS-10R NBGT-GS-12.5R NBGT-GS-15R Ball nose insert endmill for hardened steel NBGT-HS-5R NBGT-HS-6R NBGT-HS-8R NBGT-HS-10R NBGT-HS-12.5R NBGT-HS-15R NBGT-HS-16R Coner radius insert endmill for hardened steel JRGT-HS-100 JRGT-HS-110 JRGT-HS-120 JRGT-HS-130 JRGT-HS-160 JRGT-HS-170 JRGT-HS-200 JRGT-HS-210 JRGT-HS-250 JRGT-HS-260 JRGT-HS-300 Coner radius insert endmill for hardened steel HRGT-HS-100 HRGT-HS-120 HRGT-HS-130 HRGT-HS-160 HRGT-HS-170 HRGT-HS-200 HRGT-HS-210 HRGT-HS-250 HRGT-HS-260 N-i90A INSERTS & HOLDERS APKT11T308PDER-NM APKT1705PEER-NM Shank Type Holders I90A11R2016S16 I90A11R3020S20 I90A11R3025S25 I90A11R4032S25 I90A11R5040S32 I90A17R2025S25 I90A17R3032S25 I90A17R4040S32 |

Cutter Type Holders I90A11R5040C16 I90A11R5050C22 I90A11R6063C22 I90A11R8080C25.4 I90A11R9100C31.75 I90A17R4040C16 I90A17R4050C22 I90A17R5063C22 I90A17R6080C25.4 I90A17R7100C31.75 Short Flat End Mill NFM40-0245 NFM40-0450 NFM40-0555 NFM40-0655 NFM40-0860 NFM40-1070 NFM40-1275 Medium Flat End Mill NFM40-0250 NFM40-0455 NFM40-0560 NFM40-0660 NFM40-0870 NFM40-1080 NFM40-1280 Long Flat End Mill NFM40-0255 NFM40-0460 NFM40-0560 NFM40-0680 NFM40-0880 NFM40-10100 NFM40-12100 Short Ball Nosed End Mill NBH20-0445 NBH20-0655 NBH20-0855 NBH20-1065 NBH20-1270 Medium Ball Nosed End Mill NBH20-0455 NBH20-0655 NBH20-0860 NBH20-1070 NBH20-1280 Long Ball Nosed End Mill NBH20-0470 NBH20-0680 NBH20-0890 NBH20-10100 NBH20-12110 Shot Flat End Mill NFH40-0245 NFH40-0450 NFH40-0555 NFH40-0655 NFH40-0860 NFH40-1070 NFH40-1275 Medium Flat End Mill NFH40-0250 NFH40-0455 NFH40-0560 NFH40-0660 NFH40-0870 NFH40-1080 NFH40-1280 Long Flat End Mill NFH40-0255 NFH40-0460 NFH40-0560 NFH40-0680 NFH40-0880 NFH40-10100 NFH40-12100 |

Corner Radius End Mill NRH40-0455-R0.3 NRH40-0455-R0.5 NRH40-0560-R0.3 NRH40-0560-R0.5 NRH40-0660-R0.3 NRH40-0660-R0.5 NRH40-0660-R1 NRH40-0870-R0.3 NRH40-0870-R0.5 NRH40-0870-R1 NRH40-0870-R1.5 NRH40-0870-R2 NRH40-1090-R0.3 NRH40-1090-R0.5 NRH40-1090-R1 NRH40-1090-R1.5 NRH40-1090-R2 NRH40-1290-R0.5 NRH40-1290-R1 NRH40-1290-R1.5 NRH40-1290-R2 Corner Radius End Mill NRH40-0455-R0.3 NRH40-0455-R0.5 NRH40-0560-R0.3 NRH40-0560-R0.5 NRH40-0660-R0.3 NRH40-0660-R0.5 NRH40-0660-R1 NRH40-0870-R0.3 NRH40-0870-R0.5 NRH40-0870-R1 NRH40-0870-R1.5 NRH40-0870-R2 NRH40-1090-R0.3 NRH40-1090-R0.5 NRH40-1090-R1 NRH40-1090-R1.5 NRH40-1090-R2 NRH40-1290-R0.5 NRH40-1290-R1 NRH40-1290-R1.5 NRH40-1290-R2 |